Project Description

CERAMIC FILTER

Flue gas treatment by ceramic filter

The flue gas treatment system developed by Ati Industries will meet the European standards of emission gas from waste incineration plant dictated by the Directive 2000/76/CE of December, 04th 2000, and the regulation of September 20th 2002.

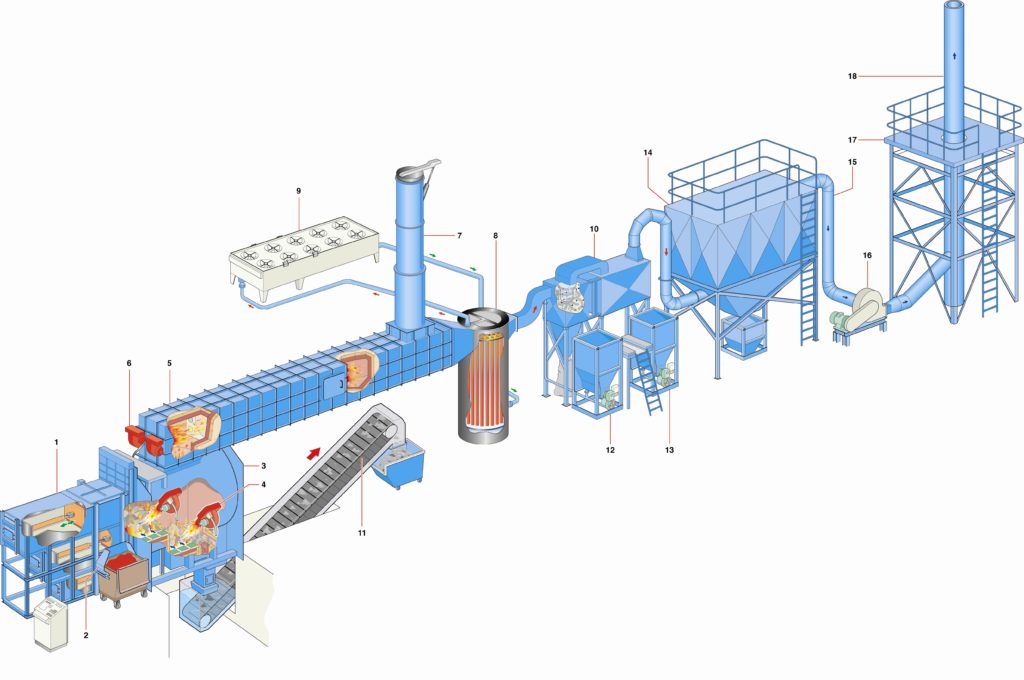

Principle of operation of a filtration line

The benchmarks listed below correspond to the diagrams of the installation (see previous page) of the technical description.

1. The gases from the incineration are led to the heat exchanger (item 8) through the post combustion sheaths.

2. The heat exchanger (item 8), coupled with an aero cooler (item 9) allows the temperature of the smokes to be lowered to between 200 ° C.

3. At the outlet of the heat exchanger (item 8), the gases are at a temperature around 200 ° C, temperature corresponding to the reaction ranges of the treatment products. At this stage, it is necessary to inject reagents to remove the pollutants contained in the smokes:

- For acid gases:

- HCl

- S02

- HF

- For heavy metals and other compounds:

- Hg

- Dioxins

- Furans

4. These neutralizing products, stored in two storage hoppers (item 12 & 13), are dosed by a specific screw depending on the needs, and injected through a reactor.

5. The reactor produces an intimate mixture between the gas flow and the neutralizers to reduce pollution.

6. A ceramic filter (item 14) is designed to trap dust, the reagents injected into the smoke and the product of their reaction.

7. An extractor (item 16) ensures that the entire filtration line is kept under vacuum. It allows the evacuation of the smokes thus treated by the chimney (item 18).

8. The chimney (item 18) is provided with all the regulatory stitching to allow through these sampling hatches to carry out the control of atmospheric discharges.

REQUEST INFORMATION

Do you need more information about your project? Please fill up the form, we will contact you as soon as possible.

PHONE

+332 38 29 29 02

EMAIL ADDRESS

info@ati-industries.eu

WORKING HOURS

08h00 – 18h00

PHONE

+332 38 29 29 02

EMAIL ADDRESS

info@ati-industries.eu

WORKING HOURS